Copyright 2020 Warren L. Herron

TM

The Future is Lighter!

TM

Lightweight Panels

Tri-combTM will lower your costs and help you make better products.

12 Tri-combTM panel benefits:

1. Possibly the strongest lightweighting structures ever invented. They

have been tested by Stress Engineering Services, Inc., so you don’t

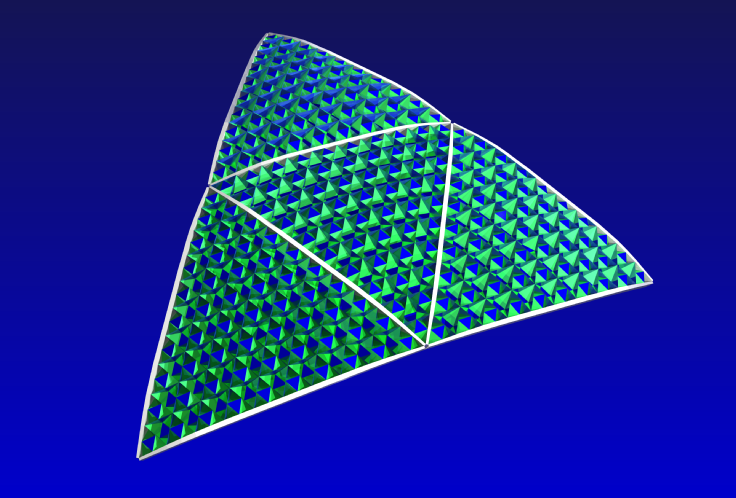

have to believe us. See the About Tri-combTM page

2. Easily mass produced - flat or curved (within limits) - in any moldable material

using simple 2-part molds.

3. Whatever you make or design can probably be both lighter and stronger.

4. Cut manufacturing costs with high efficiency material savings - without sacrificing any strength.

5. Tri-combTM was initially invented for molding. Molding is still the cheapest and fastest production technology for many mass production engineered products. We can help guide you to design more cost effectively for molding with Tri-combTM.

6. Ideal for 3D printed parts. Using these designs allows less material to do more,

resulting in compounded savings in material costs and potentially much

shorter print times for every part made. The designs allow for even lighter

weight components than using less effective geometry. Curved parts that

are impossible to mold can be 3D printed. If you want to cut weight - this is

the answer.

7. Designing can be easy using CAD programming systems. We have

developed three customizable Grasshopper® , Tri-combTM Panel

Creation Programs that run in Rhinoceros®. Create an entirely new,

finished, 3D solid, flat, multi-cell panel or a single cell, in a few seconds.

More complex designs can easily and quickly be assembled from separately

produced panels or cells to suit the desired design requirements.

8. Tri-combTM is patented in the U.S.A. and abroad, giving licensees a very real competitive edge in technology and the global marketplace.

9. Tri-combTM is striking and beautiful, giving your products a unique visual distinction. We believe it will soon be a much sought after look that will be the new face of high tech performance engineered design. We’ve won 3 prestigious design awards, which can be referenced in your marketing, proving your products are on the bleeding edge of innovative modern design excellence. Honeycomb is now the “old” hi-tech stuff...

10. Ultra efficient and Green, Tri-combTM helps conserve precious resources.

11. Panels can be fine tuned for diverse application requirements to increase efficiency to even higher levels for very demanding product requirements.

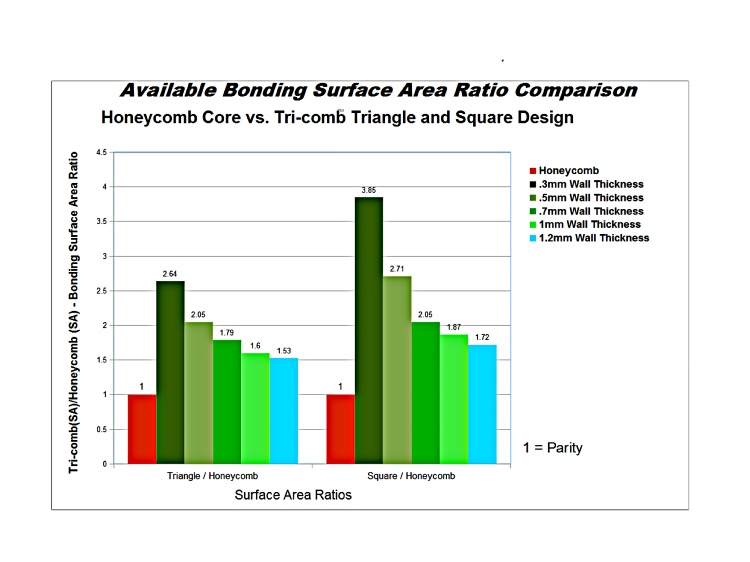

12. Laminating Tri-combTM is absolutely unnecessary for strength as long as loads are distributed, though it will increase the strength even more. Because of the buttressed design, our panels have far more surface area than honeycomb cores, for enhanced, secure bonding if lamination is desired. (See chart below)

Bottom Line - Tri-combTM is stronger, lighter, more cost effective and adaptable. It gives you, your designers and engineers a brand new palette of highly efficient design options. It allows you to be clearly innovative and even more competitive. It enables you make things that have never been possible before. The Future is Lighter!TM

Why Tri-combTM?

For more information or to set up a meeting to discuss licensing

please email: warren_herron@tri-comb.com

or contact us.